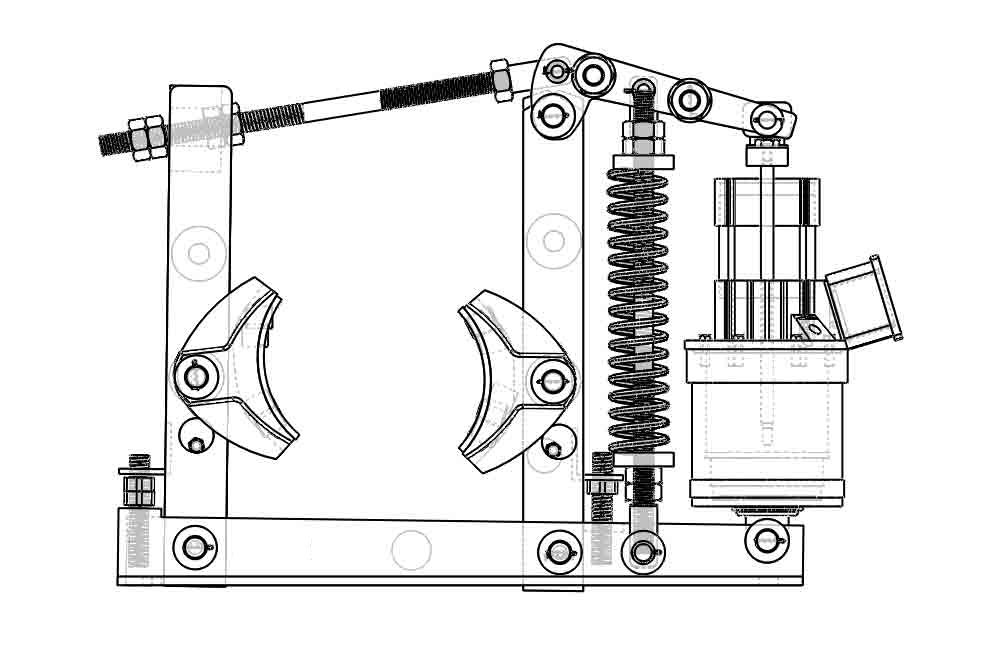

Vijayalaxmi Enterprises is one of the leading Thruster Brake Manufacturers offering a range of high quality products to several industries. The thruster brake typically consists of a hydraulic or electric actuator that applies a disc brake to the propeller or thruster shaft. When the brake is engaged, the disc is clamped against the shaft, causing it to stop rotating.

Thruster brakes are designed to provide high braking torque and are capable of stopping a propeller or thruster quickly and safely. They are also designed to withstand harsh marine environments and are often made from materials that are resistant to corrosion and erosion.

The company uses premium materials in the production of their thruster brakes, including high-grade steel and durable alloys. These materials ensure that the brakes are robust and long-lasting., Modern technology plays a crucial role in the manufacturing process at Vijayalaxmi Enterprises. Advanced machinery and computer-aided design (CAD) systems are employed to create precise and reliable components.

Standard Thruster Brakes

Their standard range of thruster brakes includes models that cater to a variety of industrial applications. These brakes are known for their reliability and ease of installation.

Custom Thruster Brakes

For clients with specific requirements, Vijayalaxmi Enterprises offers custom thruster brakes. These are designed based on detailed specifications provided by the client, ensuring optimal performance.

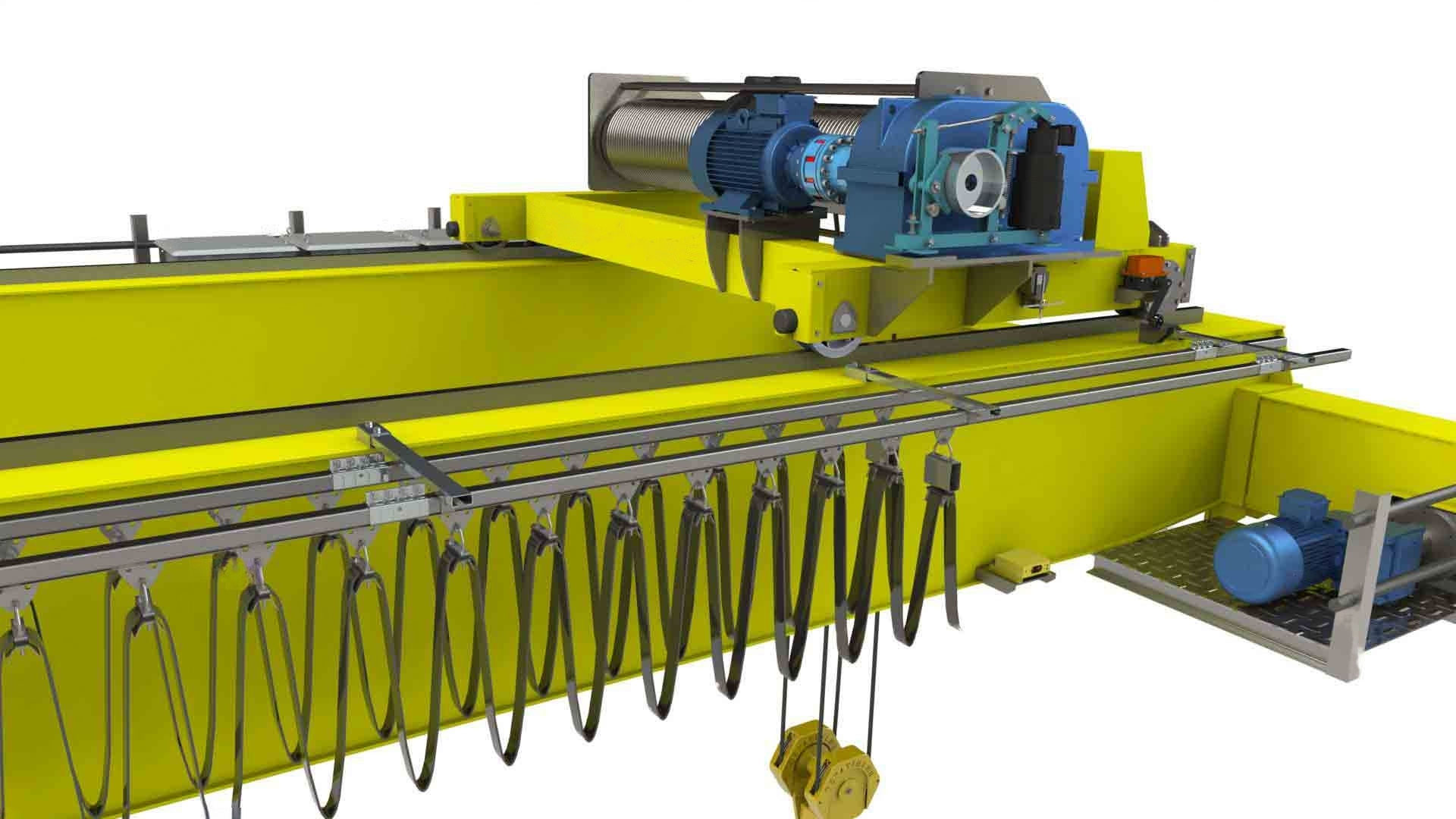

Vijayalaxmi Enterprises’ thruster brakes are known for their durability and reliability. Constructed with high-quality materials and advanced technology, they offer long-lasting performance even in demanding environments., Thruster brakes are mechanical devices that use a thruster motor to apply braking force. In an EOT crane, they are used to hold or stop the crane's load or the movement of the trolley and bridge.

Thruster brakes are critical for :

Control : Allow precise control over the crane's movement.

Safety : Ensure the crane stops or holds in place to prevent accidents and damage.

Stability : Maintain load stability during operation.

Electromagnetic Thruster Brakes

These brakes use an electromagnetic force to engage and disengage the brake. They offer reliable performance and are commonly used in various industrial applications.

Spring-Applied Thruster Brakes

Spring-applied brakes use a spring mechanism to apply the brake force. They are known for their fail-safe operation, meaning they automatically engage the brake if the power fails.

Hydraulic Thruster Brake

Hydraulic brakes use hydraulic fluid to generate braking force. They are suitable for applications requiring high braking power and smooth operation.

| Specification | Description |

|---|---|

| Model | [Model Number] |

| Type | Electromagnetic / Spring-Applied / Hydraulic |

| Braking Force | [Maximum Braking Force] |

| Rated Voltage | [Voltage Rating] |

| Frequency | [Frequency] |

| Phase | [Number of Phases] |

| Power Consumption | [Power Consumption] |

| Duty Cycle | [Duty Cycle] |

| Operating Temperature Range | [Temperature Range] |

| Dimensions | [Length x Width x Height] |

| Weight | [Weight] |

| Material | [Construction Material] |

| IP Rating | [Ingress Protection Rating] |

| Mounting Type | [Mounting Type] |

| Brake Pad Material | [Brake Pad Material] |

| Certification | [Certifications] |

| Safety Features | [Safety Features] |

| Warranty | [Warranty Period] |

| Installation Instructions | [Installation Instructions] |

| Maintenance Requirements | [Maintenance Requirements] |

• Model : Indicates the specific model number of the thruster brake, useful for identification and ordering.

• Type : Specifies the type of thruster brake, such as electromagnetic, spring-applied, or hydraulic.

• Braking Force : The maximum force that the brake can apply to stop or hold the load.

• Rated Voltage : The voltage at which the thruster brake operates efficiently.

• Frequency : The operating frequency of the brake, important for compatibility with power supply.

• Phase : Indicates whether the brake operates on single-phase or three-phase power.

• Power Consumption : The amount of electrical power the brake consumes during operation.

• Duty Cycle : Defines the operational cycle of the brake, including periods of operation and rest.

• Operating Temperature Range : The temperature range within which the brake operates effectively.

• Dimensions : Physical size of the brake, including length, width, and height.

• Weight : The weight of the brake, which can affect installation and support requirements.

• Material : The materials used in the construction of the brake, impacting durability and performance.

• IP Rating : The Ingress Protection rating indicating the brake’s resistance to dust and water.

• Mounting Type : Specifies how the brake is mounted, which affects installation.

• Brake Pad Material : Material used for the brake pads, affecting friction and wear.

• Certification : Industry certifications that the brake meets, ensuring quality and safety standards.

• Safety Features : Features designed to enhance safety, such as fail-safe mechanisms.

• Warranty : The duration and terms of the warranty provided with the brake.

• Installation Instructions : Guidelines for installing the brake correctly.

• Maintenance Requirements : Information on the upkeep needed to ensure the brake’s long-term performance.

What is the main function of a thruster brake in an EOT crane?

Thruster brakes provide reliable stopping power and precise control to hold or stop the crane’s load or movement.

What are the different types of thruster brakes available for EOT cranes?

The main types are electromagnetic, spring-applied, and hydraulic thruster brakes.

How do I choose the right thruster brake for my EOT crane?

Consider factors like load capacity, environment, and duty cycle, and ensure compatibility with your crane’s specifications.

What maintenance is required for thruster brakes?

Regular maintenance includes inspection, adjustment, and cleaning to ensure optimal performance and longevity.

Where can I find reputable suppliers for thruster brakes?

Look for trusted manufacturers with a strong industry reputation and good customer service.